In the face of dwindling forest resources and the underutilization of agricultural waste, a group of students from Tra Vinh University has developed an innovative material: engineered wood made from rice straw. This breakthrough presents a promising, eco-friendly alternative in the construction materials sector. By transforming rice straw—which is often burned post-harvest—into a durable, moisture-resistant, termite-proof product that meets technical standards, the project not only addresses environmental concerns but also holds broad application potential in interior design and construction. It marks a significant step toward the advancement of recycled materials and the promotion of a circular agricultural economy.

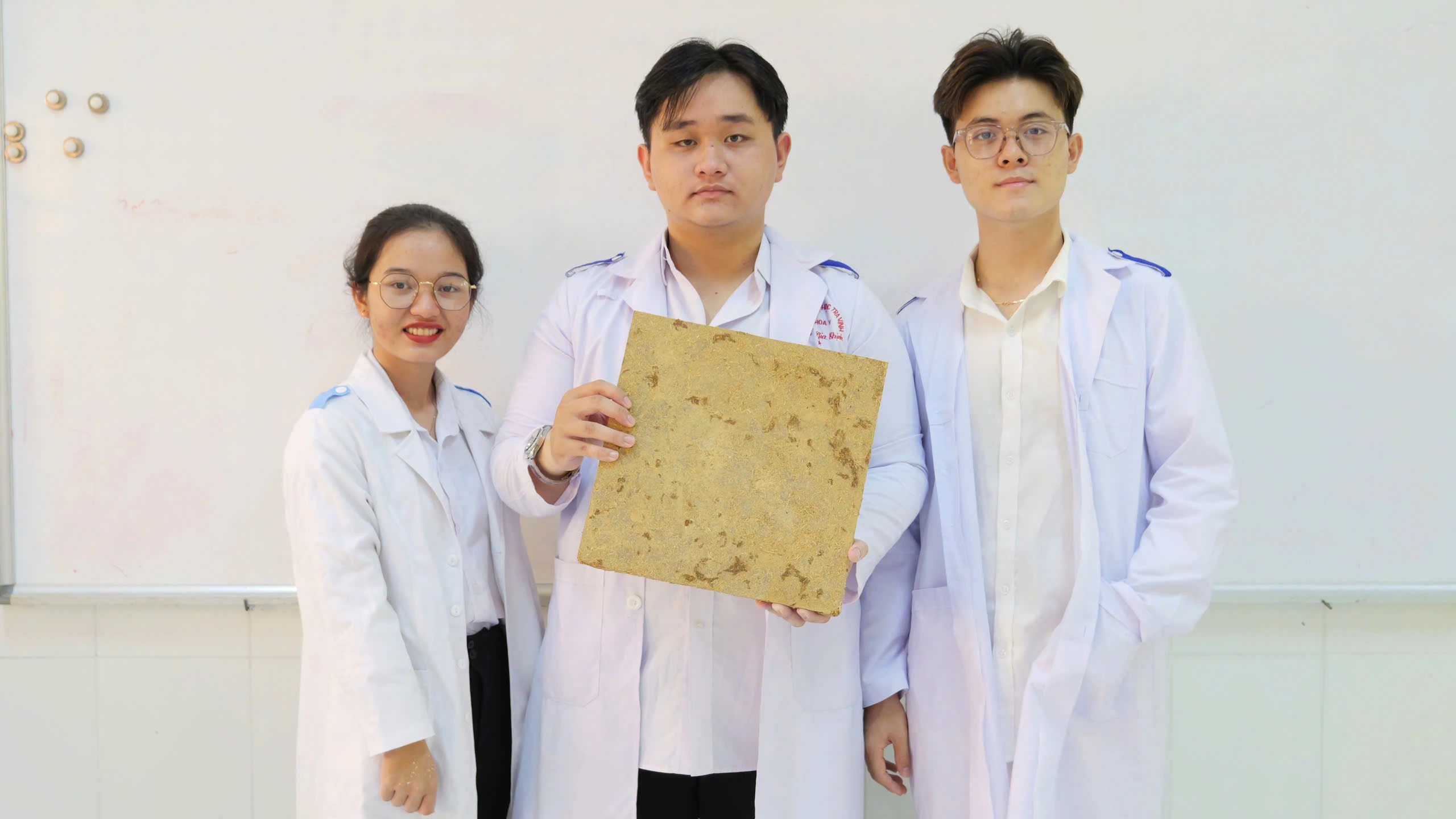

The “Engineered Straw Wood Production” project by students at Tra Vinh University won first prize in the 2024 “Startup Ideas for Students at Tra Vinh University” competition, and further claimed top honors at the Global Vietnamese Business Startup (GVB Startup 2025) competition in London, UK. The initiative introduces a sustainable alternative to natural wood by combining rice straw with bio-adhesives to create eco-friendly insulation materials. Conceived by students Tran Minh Man, Nguyen Xuan Thanh, and Nguyen Thi Thuy Duong, the project showcases the creativity and social responsibility of Vietnam’s next generation of entrepreneurs.

Project Concept

The idea behind using rice straw for engineered wood stems from two pressing issues: the inefficient use of post-harvest rice straw, which is often burned and causes environmental pollution, and the overexploitation of natural forests to meet the rising demand for wood, which continues to push up the cost of industrial wood products. Recognizing this, the student team aimed to repurpose straw into a high-utility, durable, and environmentally friendly material suitable for the construction and furniture industries.

Nguyen Xuan Thanh, a team representative, shared: “The Mekong Delta has ideal conditions for rice cultivation, resulting in a large quantity of straw each harvest season. While straw is used in various ways, burning it remains common, leading to waste and environmental harm. This reality inspired us to develop engineered wood from straw.”

Team member Tran Minh Man added: “Much of the harvested straw goes to waste. Additionally, excessive logging to meet wood demand is accelerating the degradation of natural forests. Meanwhile, the cost of industrial wood remains high. Our goal is to create an affordable, environmentally responsible alternative by turning straw into engineered wood.”

Tran Minh Man, an Information Technology major, serves as the project’s founder and leader, managing technical development. Nguyen Xuan Thanh is in charge of communications, international partnerships, and market development. Nguyen Thi Thuy Duong oversees financial planning, cost control, and resource management to ensure the project’s feasibility. Legal support from university law faculty is also assisting with intellectual property protection, which is currently underway.

Regarding production, Man explained that the team collects straw from local farmers, grinds and dries it, then uses high-capacity presses and dryers along with adhesives, binders, and termite-resistant agents to produce durable boards with standardized moisture and pest resistance.

Key Advantages of Engineered Straw Wood

The engineered straw wood developed by the Tra Vinh University team offers notable advantages over conventional industrial wood. Foremost, it boasts excellent termite and weather resistance thanks to an optimized adhesive formula, helping prevent rot and deformation in outdoor environments.

Another major benefit is its low production cost, which enhances market accessibility and competitiveness against traditional wood alternatives.

Technically, the straw wood meets stringent quality standards for strength, health safety, and environmental sustainability. Specifically, it emits formaldehyde at only 0.02 mg/L—equivalent to E0 grade (EN 717-1)—an almost zero-emission level, making it entirely safe for users.

Impressive Physical and Mechanical Properties:

Minimum elasticity of 2,500 MPa, over 20% higher than many industrial wood products, ensuring good flexural strength and reducing the risk of cracking during use.

Static bending strength of 18 MPa, 25% higher than standard, supporting high-load applications in furniture and structural use.

Excellent moisture resistance, with swelling after 24 hours of water immersion below 5%, half the standard threshold for particleboard, ensuring shape stability in humid environments like kitchens and bathrooms.

Abrasion resistance above 95%, more than 30% higher than natural wood, making it especially suitable for Vietnam’s hot, humid climate and high-wear areas.

These strengths position straw-based engineered wood as both an effective alternative to natural wood and a green, sustainable solution for the construction and interior design sectors.

Economic Value and Commercial Potential

Trial results show that 25 kg of dry straw can yield approximately 2 m² of engineered wood. The production process—drying, grinding, adhesive mixing, and pressing—resembles current particleboard manufacturing methods. The product meets Vietnam’s TCVN 9311-1:2012 fire safety standards, with a minimum fire resistance of 30 minutes. Its tensile strength of at least 1.5 MPa surpasses industrial wood benchmarks by 15%, ensuring durability under real-world conditions.

In contrast to mushroom farming models that produce only 2–3 kg of mushrooms over 25–30 days using the same amount of straw, converting straw into wood offers significantly higher economic returns. With an estimated market price of 170,000 VND/m², the product has promising commercial prospects in construction, green architecture, and interior design.

The product complies with ISO 14001 environmental management standards and is recognized as an eco-friendly material by utilizing recycled inputs, reducing CO₂ emissions, and discouraging open-field straw burning after harvests.

Chemical resistance tests show the material maintains weight, hardness, and surface quality when exposed to common agents like mild acids, alkalis, and solvents, making it viable for industrial environments and chemically intensive applications.

According to the team, the product aims to resolve the limitations of traditional industrial wood, such as low abrasion resistance, poor bendability, and quick outdoor degradation. Their engineered straw wood excels in these areas while remaining more affordable. The group is now working with designers to refine aesthetics and scale up production for market entry.

Challenges in Implementation

One major challenge the team faced was optimizing the adhesive formula to balance bonding strength, mechanical durability, and user safety. This required several months of continuous testing to determine the right blend ratios.

Financial constraints also posed a common hurdle for student entrepreneurs. However, the project has received strong support from local agencies, including the Department of Science and Technology, the Department of Planning and Investment, and especially the Tra Vinh Business Incubator. These resources have been crucial in sustaining operations and product development.

Future Outlook

Through this project, the student team aims to convey a message about harnessing agricultural byproducts to generate new economic value while reducing pollution and increasing farmers’ incomes.

Looking ahead, the team plans to refine production processes, expand partnerships with businesses, and accelerate market promotion. Their long-term goal is to establish a sustainable production model that reshapes perceptions of rice straw in both agriculture and industry.

The “Engineered Straw Wood Production” project not only demonstrates a creative use of agricultural residues but also embodies the spirit of green entrepreneurship and social responsibility among youth. Leveraging technology to transform what was once considered waste into a sustainable building material, the initiative is paving a new path for Vietnam’s materials industry. Beyond local and international accolades, the team is steadily moving toward commercialization, contributing to the growth of a circular economy and forest conservation efforts.

The project stands as a compelling example of student innovation, where academic knowledge is fused with entrepreneurial drive and a commitment to creating practical value for society.